Wood Substrate Method to Strengthen a Marble Top

The wood substrate method is a technique used to strengthen marble tables, particularly those with thinner slabs or intricate designs that may be prone to cracking or breaking under stress. This method involves attaching a wood substrate, usually plywood, multiplex or MDF (medium-density fiberboard), to the underside of the marble slab.

Here’s how the process works:

1. Selection of Wood Substrate

- Material Choice: The substrate is typically made from a durable and flat material like plywood, multiplex or MDF, chosen for its strength, stability, and ability to adhere well to marble.

- Thickness: The thickness of the wood substrate is selected based on the marble’s thickness and the table’s intended use. Generally, 1/2-inch to 3/4-inch thick substrates are used.

2. Preparation

- Cutting the Substrate: The wood substrate is cut to match the dimensions of the marble slab, ensuring that it fits perfectly underneath.

- Surface Preparation: Both the marble and the substrate surfaces are cleaned and prepared to ensure a strong bond. The marble surface is often roughened slightly to enhance adhesion.

3. Adhesion Process

- Adhesive Application: A flexible adhesive designed for stone is applied evenly across the wood substrate.

- Bonding: The marble slab is carefully placed on top of the adhesive-coated substrate, ensuring alignment. Pressure is applied evenly across the surface to ensure a strong bond without air pockets.

4. Securing the Bond

- Clamping: The table is clamped or weighted down to ensure consistent pressure across the entire surface while the adhesive cures. This prevents any movement that could weaken the bond.

- Curing Time: The adhesive is allowed to cure for the recommended time, typically 24-48 hours, to achieve maximum strength.

Benefits of the Wood Substrate Method

- Enhanced Sturdiness: This method significantly increases the overall strength of the marble table, reducing the risk of cracking, sagging or breaking.

- Longevity: It prolongs the life of the table by providing additional support, especially for tables that are frequently used or moved.

- Aesthetic Integrity: The method allows for the preservation of the marble’s aesthetic while adding structural integrity, ensuring that the beauty of the stone is maintained without compromising on durability.

This method is particularly useful for custom marble tables, when using thin marble slab, when a slab has a natural hairline cracks or has intricate cutouts, ensuring that the final product is both beautiful and robust.

Below are some examples of where the Wood Substrate Method is used.

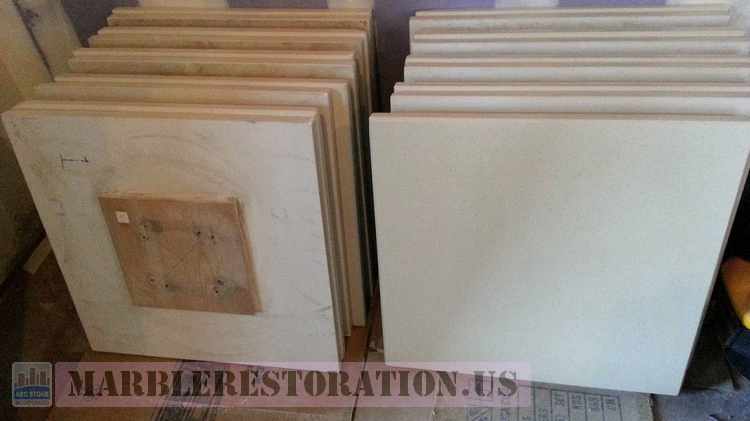

Multiplex Plywood Substrate under Knoll Table

Chipboard Substrate Base

Plywood under Corian Conference Table

Onyx Bar-Top Supported by Multiplex Plywood

Veneer Marble on Multiplex Plywood Base

Baseplate on Caesarstone Cafe Tables

Wooden Leg with Cross Supporting Planks

Dining Table Freely Laying on Substrate Base

Wooden Landing Step as Supporting Base

Store Countertop with Underlying Plywood

Marble Base with Tempered Hardboard

Wooden Fixation on Expandable Dining Table

Round Base Frame for a Coffee Table

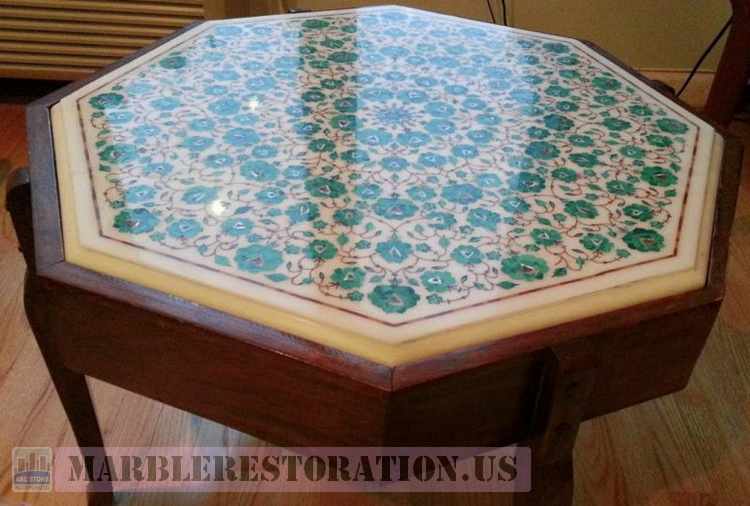

Hexagon Table Laying in Wooden Niche

Window Sill with Multiplex Plywood Underneath Supporting

Submit Your Order or Ask a Question :

You'll get a response within a few minutes or hours and usually not longer than 24 hours.