Countertop Seams Repair Service

If we consider countertop fabrication from even high-quality stone, most often, it is impossible to do without a seam or joint on the counter. An invisible seam can only be made on acrylic, and not on natural stone or on quartz, such materials cannot be seamlessly melted. If it is invisible on the countertop or at an integrated sink – this suggests that more likely you have a plastic or acrylic product.

Natural stone and man-made agglomerate come to fabrication in slabs – large plates, from which the countertop is subsequently made. The sizes of these slabs are not infinite – granite usually comes with a width of more than 10 feet, marble up to 10 feet, and quartz slabs have standard sizes of 55,5″ x 122″.

Countertops in places like sink or cooktop cutouts are quite likely to break during installation or during transportation. When the item is large or the countertop is L-shaped, the seam on the countertop should be in any case. It is reasonable to make a joint in narrow places like by the sink, due to which the line does not cross the countertop entirely and does not “strike” the eye at all.

How the seam will look on a stone?

This is not a simple question, and sellers quite often do not know how the seam will look after re-bonding the slabs together. This can be unpredictable because on different stones the joint line will look differently. Worse, if the seller claims that the joint will not be visible at all because this means that you are going to order a plastic countertop.

The crevice width on the stone can vary from 0.3 mm to 1.5 mm, depending on the physical properties of the stone. How much the line will be noticeable, will depend on the kind of stone, its texture, pattern, and color.

Installers need to mix glue with pigments to match the stone color as closely as possible and with full compliance with its pattern. A seam line on a countertop in most cases will not catch the eye, but there are disappointments in life when a countertop is made of light one-tone marble, and the installers have little experience, and could not correctly tint the glue.

5 factors will influence seam visibility:

- Stone color:

With color, everything is simple – the more various colors on the stone, the less noticeable the seam. Light monotonous colors (white, beige, yellow, transparent, etc) will have a more noticeable line than in the dark. Variegated and intensive colors (red, green, brown, gray, etc.) are the best to hide the gap. On black slabs, the visibility increases again, as its monotonous color. - Minerals grains:

When the grains are not expressed and the stone color is solid, in this case, the joint line on the stone will be more noticeable.

When grains look like sugar on marble, the edge after the cut turns out to be somewhat torn, and this also underlines the edges and makes the width thicker.

When it comes to fine-grained granites, even if they are plain, the seam will be more accurate than on plain marble, due to the granularity of the granite.

Coarse-grained granites will also have very thin and neat joints, but not all grains will fall on each other. The seams on the granite countertop with large grains will be more detectable than the seam on the countertop made of fine-grained or medium-grained granites. - Quality of the edge after cutting:

The edge quality of the seam is directly dependent on the quality of the saw blade with which the stone is being cut. The rock granularity and internal structure are different for each stone, but if the saw blade is of poor quality, the edge will get many chips. Then they should be filled with colored epoxy and it will make the seam line inconsistent and more unnoticeable. - Experience of installers:

The result also depends on the installer’s experience. How they will adjust the slabs evenly, polish the seams without altering the surface finish, tint glue for maximum similarity, etc. The practice with different teams shows the installer with experience in a workshop will give a high class of professionalism in the stone business.

Common Problems and Challenges:

- Color matching:

Finding an exact color match for the stone can be challenging, especially if the countertop is made from a unique or rare stone. In some cases, it may be necessary to mix multiple epoxy colors to achieve the desired shade. - Adhesive selection:

Using the wrong type of adhesive or mixing it incorrectly can lead to bonding issues or discoloration. It’s essential to use a high-quality epoxy adhesive specifically formulated for use with stone countertops. - Seam visibility:

Even with careful repair work, seams in stone countertops can sometimes remain visible, especially if the countertop was poorly installed or if the slabs has shifted over time. In some cases, additional work may be needed to minimize the appearance of the seam. - Structural integrity:

Seam repair is not just about aesthetics; it’s also essential to ensure that the repaired area is structurally sound and able to withstand normal wear and tear. This may require reinforcing the seam with additional support or using specialized techniques to strengthen the bond.

Overall, seam repair in stone countertops requires attention to detail, patience, and a thorough understanding of the properties of stone and the materials used in the repair process. Hiring a professional with experience in stone seams repair is often the best way to ensure a successful outcome.

How the seam on stone countertops should look like?

What are the right seam width and color should be when joining stone slabs?

What does the seam visibility depend on?

Request a price for your seam repair:

You'll get a response within a few minutes or hours and usually not longer than 24 hours.

Seam Repair – Before & After

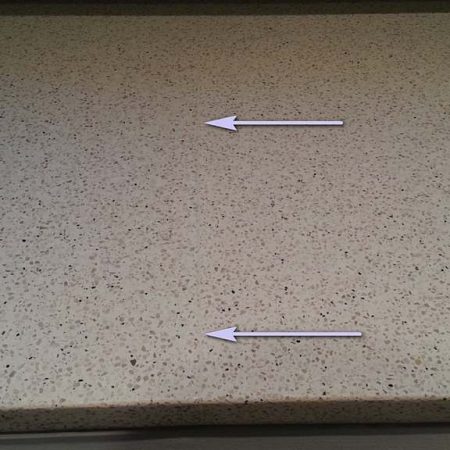

Caesarstone Poorly Filled Seam before Epoxy Filling Up

The poorly filled seam on Caesarstone is cleaned from old glue by cutting it out and more…

Caesarstone Hidden Seam (Blended Tints)

Not every marble installer or general contractor can be good enough for seaming coun more…

Seam Line on Granite Island before Rehab

The poorly filled seam on this counter island is very obvious and deep. More likely more…

Unnoticeable Seam on Granite after Flattening and Smoothing

We’ve removed some old epoxy from the top of the seam, then cleaned up the gap with more…

Poorly Filled Seam on Bathtub Top before Rebonding

Seams repair Q&A: Should the tub top be replaced? – NO. Does poorly filled seam more…

Fixed Seam on Botticino Tub Top

For best hiding a seam or crack on multicolored marble we prepare and use a few colo more…

Dislodged Sink Seam Before Rehab and Slab Lifting. Golden Oak Granite

This dislodged seam expansion caused by shifting down the opposite side of the entir more…

Sink Seam after Re-bonding

Front seam of golden oak granite countertop was filled up with colored epoxy, flatte more…

Marble Seam Expansion in Front of Cooktop

The poorly filled seam expansion may occur when new kitchen cabinets setting down un more…

Seam Fill Up and Unnoticeable Fix on Front of Cooktop

A seam can be fixed by lifting of a counter and shimming from underneath of a counte more…

Submit Your Order or Ask a Question :

You'll get a response within a few minutes or hours and usually not longer than 24 hours.